Success

Delatim contracted Burnell to design, manufacture and commission new control panels (Local Control Panels, Motor Control Centres and Electro-Pneumatic Control Panels) which operate the Jubilee Line tunnel ventilation system.

Works included a large period of surveys and designs were created for every single panel. The survey process was extensive as it involved a period of discovery. Burnell identified how the existing system functioned and how to upgrade it to bring it up to the high standard and quality of the modern day. Gathering a general knowledge and understanding of the site and system in place was paramount in preparation for the new design. Burnell looked after the design and installation components and logistics to a large extent and the design and installation programme was approved by Delatim and Transport for London prior to installation.

The MCP and LCP panels were assembled in A frames where the height could be adjusted and lowered for optimum and ergonomic working; avoiding the requirement to bend for testing and installation. Backplate builds and testing was carried out for nearly a year and a half, between April 2023 and August 2024. Burnell designed, manufactured and tested 114 panels and 88 backplates in total for the Jubilee Line.

Burnell’s first installation took place on site in July 2023 and the final installation took place in January 2025. The number of Burnell engineers working on the project was variable throughout the period. The rota averaged out to be a team of three working on site for day work and a team of three working on site at night. Both teams were accompanied by a Burnell Project Manager overseeing health and safety and plant movements. The testing process involved a team of two.

Our works featured in the majority of the package and Burnell provided management guidance to ensure the installation was carried out according to our manufacturer specification and in line with Delatim’s CDM.

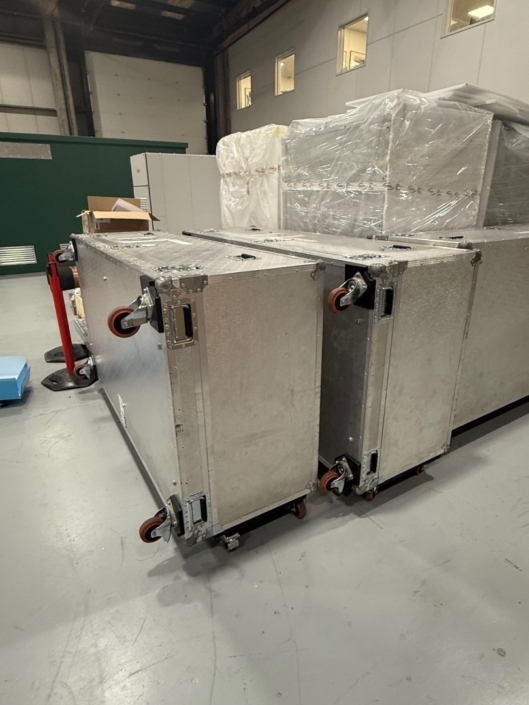

It was essential to deliver the panels on time to meet energisation dates. Burnell ensured testing and quality control was carried out at their manufacturing department in Dartford in advance and all deliveries were made to site for commissioning’s to be carried out on certain dates. Following each commissioning, all parties were enabled to move on to the next site. Meeting panel delivery times to site for an on-time-delivery of energisation was the driving force behind the project and core to all of the deliverables. A commitment to the energisation timelines was made across the board, from design to manufacturing to installation to driving to site on certain days to complete the final testing and commissioning. The wider stakeholder team included the London Fire Brigade and the LUL Power Networks team that isolated the power for the works to be carried out. In London, come midnight, the city is much quieter and without parking restrictions. Burnell were able to pull up outside the majority of stations to deliver the backplates in purpose made flight cases to manoeuvre all into location. The works were carried out between 12am and 4am to avoid any disruptions to transport services. Assembling and testing all new control panels and the headend system at Burnell’s manufacturing department rather than replacing individual components on site, enabled the installation to be carried out between the four allocated strict hours and accelerated the progress of the programme significantly.

Full credit to our management team Alexander Turner and Cliff Cooper, our site managers Rob Green and Matthew Butler and sales director Mark Osborne, whom worked with the Delatim project managers and site managers throughout the programme and carried out a lot of the work.